The MEMOLUB® ONE LPS (Low Pressure System) was developed as a very economical single-point lubricator that is particularly suited for applications that require a limited quantity of lubricant over a 1, 3, 6 or 12 month period of time.

All the MEMOLUB® lubricators use the same patented positive displacement pumping system that applies the output pressure to only the lubricant being immediately ejected into the bearing. This important feature eliminates most of the problems of grease serparation that result from systems that subject the entire quantity of lubricant to continuous pressure.

|

MEMOLUB ONE vs. MEMOLUB HPS What’s the difference? |

MEMOLUB ONE |

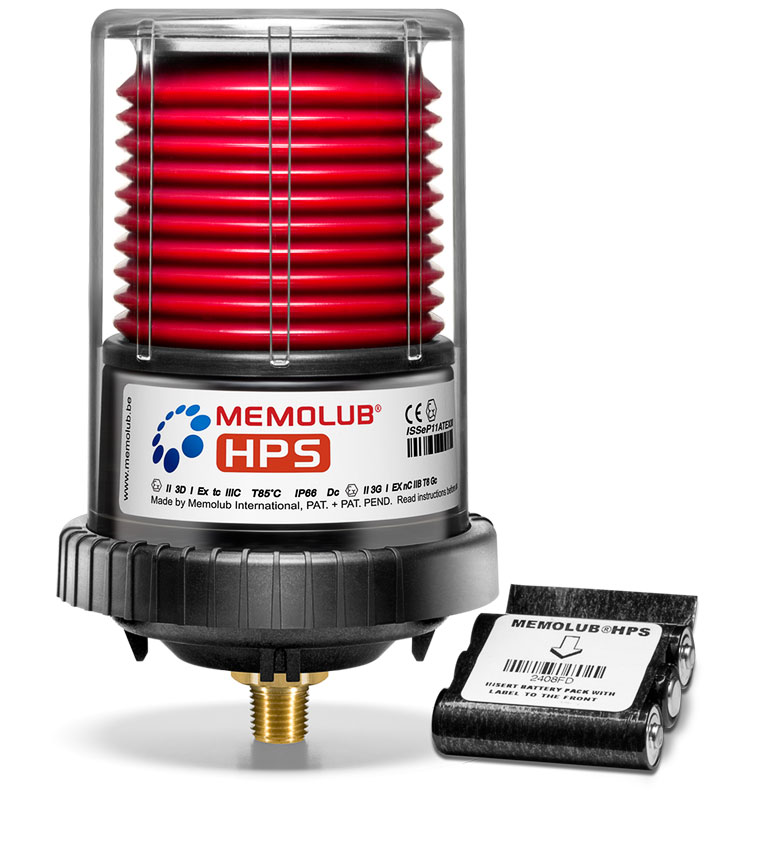

MEMOLUB® HPS |

| Maximum Operating Pressure | 140 PSI (10 bar) | 350 PSI (25 bar) |

| Power Source | Battery Pack / 4.5VDC | Battery Pack / 4.5VDC |

| Output Programming | LPS MEMO: Yellow, Green, Red and White |

HPS MEMO: Brass with Red, White and Black Timing Rings |

| External On/Off Control | No | No |

| Lubricator Timing Settings | 1, 3, 6 and 12 month | 52 Settings |

| Multi-Point Capable | No | Yes |

| Lubricant Capacity | 240 cc | 120cc, 240cc and 480cc |

| Temperature Range | +5°F to +120°F (-15°C to +50°C) | +5°F to +120°F (-15°C to +50°C) |

| Remote Installation (Single-Point) | Up to 6 feet (2 meters) | Up to 40 feet (12 meters) |

| Mounting Thread | 1/4 R Male | 1/4″ NPT Male |

| Reusable | Yes | Yes |

The MEMO regulates the rate of grease output of the MEMOLUB® HPS. It consists of a brass adapter, a black plastic timing-ring holder, and three plastic timing rings (one white, one red, and one black). The MEMO is permanently fitted onto the bearing or other component, and all MEMOLUB® HPS lubricators of any size will recognize its program setting.

The MEMO regulates the rate of grease output of the MEMOLUB® HPS. It consists of a brass adapter, a black plastic timing-ring holder, and three plastic timing rings (one white, one red, and one black). The MEMO is permanently fitted onto the bearing or other component, and all MEMOLUB® HPS lubricators of any size will recognize its program setting.

The white, red, and black plastic timing rings are used to set the frequency of ejection cycles of the MEMOLUB® HPS. They are inserted into the black plastic ring-holder either individually or in combination to obtain the desired frequency of output cycles.

The white, red, and black plastic timing rings are used to set the frequency of ejection cycles of the MEMOLUB® HPS. They are inserted into the black plastic ring-holder either individually or in combination to obtain the desired frequency of output cycles.